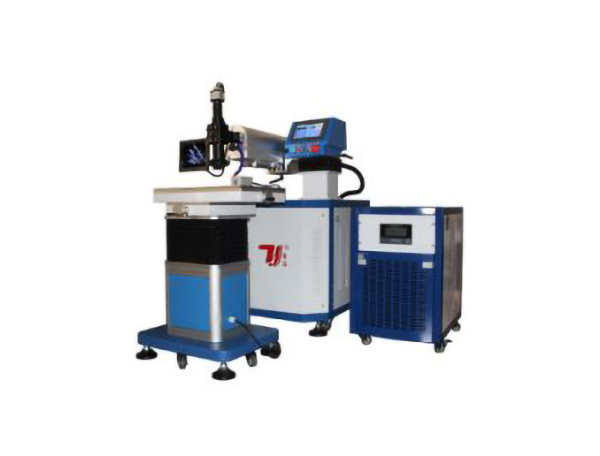

A product of the first jewelry exclusive jewelry welding machine is designed for laser welding, mainly used in the fill hole and hand soldering spot gold and silver jewelry.

Range of equipment for

A product of jewelry exclusive jewelry welding machine is designed for laser welding, mainly used in the fill hole and hand soldering spot gold and silver jewelry. Laser spot welding is one of the important aspects of the technology of laser material processing, spot welding process is hot conduction type, i.e., the laser radiation heating surface of the workpiece, the surface diffusion of heat through the heat transfer inside the guide, by controlling the width of the laser pulse energy, peak power and repetition rate and other parameters, so that the workpiece is melted, forming a specific pool. Because of its unique advantages, it has been successfully applied to silver jewelery and micro machining, welding small parts.

Machine features

Jewelry exclusive laser welding machine using a large-screen liquid crystal display Chinese interface, allows the operator to more easily learn some and operation, suitable for jewelry repair and manual welding most materials. Only a small heat affected zone, the low oxidation rate, single-point bonding energy is strong, it does not appear blisters, porosity and other phenomena, seamless welding, will not cause deformation of gold and silver jewelry.