Fiber laser cutting machine is a laser generator using an optical fiber as the light source of the laser cutting.

Optical fiber lasers is a new development of a new type of fiber laser output laser beam of high energy density internationally, and accumulated on the surface of the workpiece, so that the region to be melted and vaporized instantaneously irradiated with ultra-fine focus spot on the workpiece, by numerical control moving the spot position of the mechanical system and the automatic cutting irradiation.

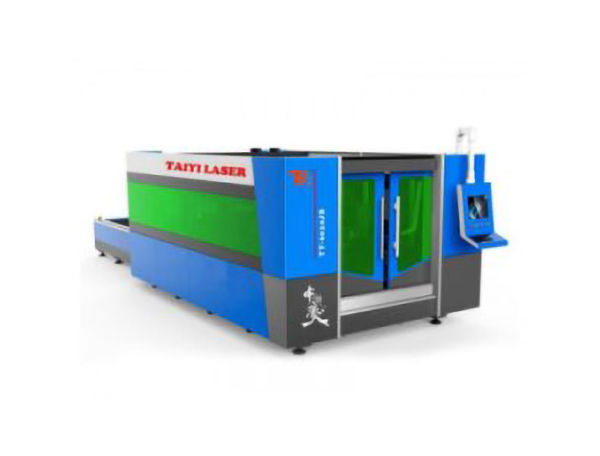

TY-3015DJG Fiber Laser cutting machine features

- A rear pipe cutting equipment power chuck, chuck front hybrid synchronous rotation drive through flat, to prevent deformation of the elastic flat on itself.

- A positioning fixture pipe cutting equipment, the cutting head is positioning fixture, the through-put due to non-standard flat positioning accuracy.

- Using optical fiber lasers, electrical – optical conversion efficiency is high, the conversion efficiency of more than 30%, can greatly save the power consumption when operating, operating cost savings, the highest productivity.

- Only need to run power lasers, gas lasers do not need to create additional, with the lowest operating and maintenance costs.

- Fiber using semiconductor lasers and modular redundancy, no resonant cavity optical lens, no start-up time, with adjustment-free, maintenance free, the advantages of high stability, reduce component costs and maintenance time, which is traditional lasers can not match.

- Before and after the work table using the bit level, simple structure, no hydraulic lifting devices, front and rear shift stage synchronization mutual exchange, fast switching speed, plate change time saving and improve work efficiency.

- Dual tube sheet, both sheets cutting, but cutting pipe, a machine.

- Wavelength fiber lasers output of 1.064 micrometers, 1/10, good output beam quality, high power density, is conducive to the absorption of a metal material having excellent cutting and welding capability, so that the processing cost of CO2 wavelength lowest.

- Optical fiber transmission routing machine, no complicated reflection mirror optical system, the optical path is simple, stable construction, the external light path maintenance.

- The cutting head comprising a cover lens, a focus lens so that expensive consumables like little consumption.

- Y are used to CNC gears, rack guide, AC servo motor, high speed, high precision.

- PC using specialized industrial computer and the numerical control system of Bayshore Chuzhi Hui, easy to operate; professional cutting control software support CAD graphics and text automatic programming, software compatibility strong, can produce a variety of text, graphics, support DXF / GERBER / PLT and other graphic formats.

- The use of US technology cutting head, cutting effect perfect.

- France adopted a planetary helical gear reducer, smooth operation, low noise, reliable performance.

- About 16 mm or less can be cut more metal materials of carbon steel, alloy steel, spring steel.

- Cutting area up to 3000mm * 1500mm, format size can be customized according to customer requirements.

- Suitable for cutting all kinds of precision machine parts and cutting panels, perforated metal, and various characters, decorative patterns and the like. Trimming little affected by heat, slit formation, substantially no thermal deformation of the workpiece, generally does not require secondary machining slit.

- Separate design focal length follow, even if the material surface irregularities can ensure the cutting quality impact, from the shape of the workpiece, good flexibility laser processing, can be processed in any pattern.

- Saving investment mold, shown in the image can be carried out on any computer laser processing, no mold, the mold is not consumed, not repair of the mold, the mold replacement time saving, saving processing costs, reduce production costs, especially for large product workpiece.

- Specific operating costs: about electricity: 14 degrees / hr

Oxygen: 8 to 12-membered / hr

cover lens, nozzle: 0.2 to 0.5 / hour

in distilled water of about: 0.1 / hour

Note: If the cost per hour nitrogen purge was added 20 ~ 25.

TY-3015DJG Fiber Laser-cutting structure

TY-3015DJG genus gantry CNC laser cutting machine, dual-drive, exchange platform, an external pipe cutting apparatus. Wherein X, Y-axis cutting feed plane implement mobile gantry structure. A two-axis, Z-axis tracking the floating surface of the workpiece; the Y frame is steel precision welding, the whole high temperature annealing, stress failure processing; large gantry rail seat knife milling process, to maintain good long-term stability, X rack magnesium alloy casting integrally molding, light weight, high strength.

TY-3015DJG Fiber Laser Cutting Machine Laser cutting capability

Advise customers to choose their own machines, different power, cutting speed, and different thickness.

Kerf width narrower (typically 0.1 ~ 0.3mm), high accuracy (dimensional error generally 0.1 ~ 0.25mm / m), a good cut surface roughness (Ra is typically 3.2 ~ 25.4μm), the slit can be welded without further processing .

Technical Specification

| project name | Technical Parameters |

|---|---|

| Laser Type | Fiber lasers (1500W) |

| Laser wavelength | 1070nm |

| Electro-optical conversion efficiency | 25-30% |

| XYZ axis travel | 1510mm / 3050mm / 210mm |

| Cutout slit width | 0.1-0.2mm |

| Repeatability | ± 0.03mm / 1000mm |

| positioning accuracy | ± 0.03mm |

| The maximum air speed shift | 100mm / min |

| Maximum acceleration | 1.2G |

| Cutting sheet thickness | 0.2-16mm (depending on material) |

| Cutting pipe thickness | 1-4mm (depending on material) |

| The maximum cut length of the barrel | 6000mm |

| The maximum cutting diameter of the pipes | ¢ 140mm |

| Table largest truck | 2500kg |

| Total Weight | 6000kg |

| electricity demand | 380V 50Hz / 60Hz |

| Dimensions (length × width × height) | 7500 * 3500 * 1600mm |