Supported by experienced professionals, we are manufacturing and supplying an excellent range of Robot Gantry System. This robot system is installed to perform pick and place work and can also be used in welding and other applications. Manufactured using innovative technology in compliance with set industry standards, it ensures fast and speedy work performance. This Robot Gantry System is available in different specifications to cater the needs of our valuable clients. Moreover, it is sternly checked on various parameters.

Features:

- Low maintenance

- Sturdy design

- Long functional life

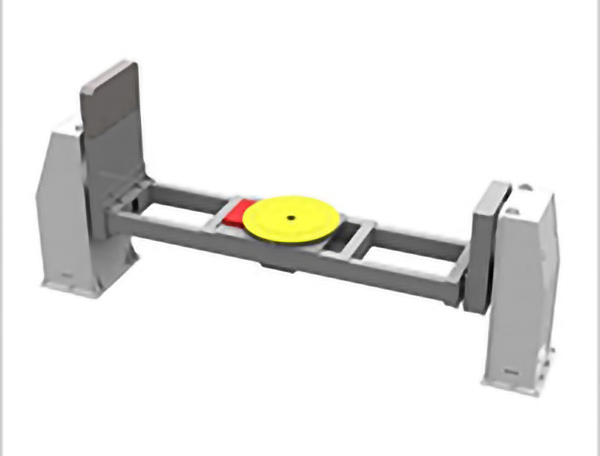

Robotic System Equipment Gantry (X,Y,Z)

Robot Gantry System

Application :

Excavator Welding Line

Information :

- Boom – Flexible Manufacture System and single robot welding station

- 8-axis synchronized robot welding system

- Single-axis headstock-tailstock positioner with payload up to 5,000kg

- Flexible hydraulic fixture for various models

- Well-developed software for arc welding of medium/thick plate

Loader Components

Information :

- Bucket – Flexible Manufacture System and single robot welding station

- 11-axis synchronized robot welding system

- 3-axis gantry system with 6-axis robot to achieve perfect working envelop and system flexibility

- C-frame positioner with payload up to 2500k

- High-efficient MAG welding system

- Well-developed software for arc welding of medium/thick plate

Specification :

| HLV03-13 | HLV03-123 | |

| Max. Speed-X | 60 m/min | 60 m/min |

| Max. Speed-Y | 60 m/min | |

| Max. Speed-Z | 20 m/min | 20 m/min |

| Effective Travel-X | 7000 mm | 5000 mm |

| Effective Travel-Y | 2000 mm | |

| Effective Travel-Z | 1500 mm | 1500 mm |

| Repeatability | + 0.1 mm | + 0.1 mm |