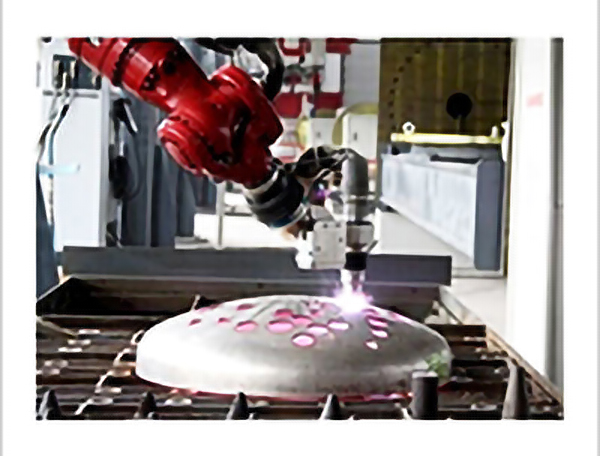

To assure the excellent performance, we bring forth a wide range of CNC Cutting System. Widely demanded in the automotive industry, this system is rigorously checked on various parameters. Broadly used for making the shafts, gears, and many other parts, this cutting system is highly acknowledged in the market for its sturdy structure, energy efficiency and corrosion resistant finish. Manufactured in compliance with set industry standards, this CNC Cutting System can be availed from us in varied technical specifications.

Standard Features:

- Hardened and ground helical pinion gears

- Precision helical gear rack

- Hypertherm Edge Connect CNC control

- Integrated SENSOR torch height control interface

- Heavy duty steel gantry construction

- Triple machined floor mounted main rails

- Flexible master carriage system for up to three tools

- Planetary gear heads

- Enclosed flexible cable carriers on Both X & Y axis

We provide :

- EcoCut CNC Flame and Plasma Cutting System

- MiniCut CNC Flame and Plasma Cutting System

EcoCut CNC Flame and Plasma Cutting System

Specification :

|

Track width |

3~11m |

|

Track length |

According to customer demand |

|

Cutting width |

track width |

|

Cutting length |

track length |

|

Cutting thickness |

1~150mm (Max300mm) |

MiniCut CNC Flame and Plasma Cutting System

Specification :

- Cutting Type: Oxy fuel or plasma

- Effective cutting range:1500x3000mm

- Rail Systems to 100 ft (30.5 m) or More

- Up to six stations

- Contour bevel system

- Up to two plasma torch height control stations

- Plasma Torch Lifter with AC Servo Driven Ball Screw

- Plasma Torch Collision Mount

- Phoenix software oxy-fuel cut chart screen captures

- Programmable Torch Selection and Spacing

- Alignment Camera

- Up to six oxy-fuel stations – straight cutting

- Digitally controlled heavy-duty electronic oxy-fuel gas manifold

- Over-head cable carriers

- Automatic Lubrication Systems

- Multi-zoned down draft air table

- Programming software

- Plate Markers (air scribe or plasma)

- Cross-hair laser pointer

- Dust collection systems

Further Details:

Selecting the Right CNC Cutting Machine

There are numerous assorted factors to consider before you get ready to invest in the CNC plate cutting machines or CNC pipe cutting machines for your business purpose. Of course, total quality, durability, dependability and cost effectiveness are the basic and important parameters to keep in the mind, on the basis of which these machines can be tested for their faultlessness.

More generally, you will want to think about the necessities for the particular widths and lengths of the materials. So before you start with it after buying think about the types of thicknesses and materials that can be precisely cut.

You have to also think about that in what amount of thicknesses cutting systems are easy to use at once, and how rapidly various types of jobs can be accomplished. Be confident to also view the kind and quality of controls and computers, which are included in the machines if they are compatible.