We are renowned as a Manufacturer and Supplier of C Frame Robotic System Equipment (C Frame Spot Welder), based in Vadodara, Gujarat, India. The offered range is designed and developed under the guidance of our team of well-experienced professionals, by using the top-notch quality components and modern techniques. All the products are designed as per the requirement of our precious customers. Furthermore, the range of C Frame Robotic System Equipment (C Frame Spot Welder) is available to us at very reasonable price.

Application :

Steam Turbine Blade

- Master-slave control, 18-axis sychronized robot welding system

- 2-axis C-support with two 6-axis robot to achieve maximum working envelop and system flexibility

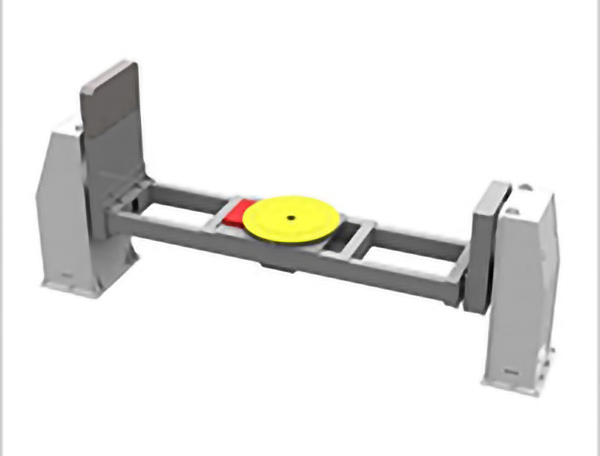

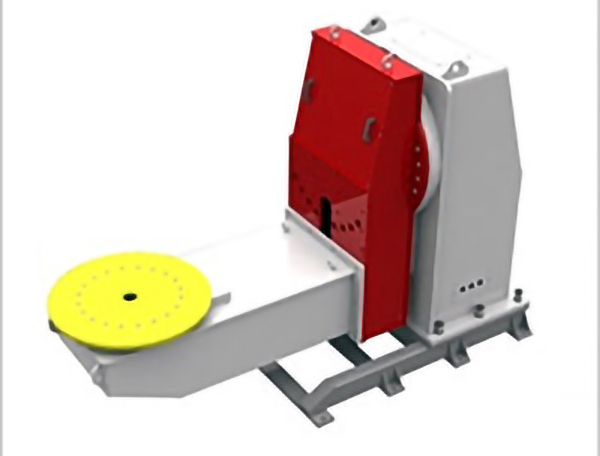

- 2-axis robot positioner with payload up to 5,000kg

- Hot wire TIG welding process

- Visual monitoring system

Seam finding and AVC control

- 2-axis C-support with two 6-axis robot to achieve maximum working envelop and system flexibility

- 2-axis robot positioner with payload up to 5,000kg

- Hot wire TIG welding process

- Master-slave control, 18-axis sychronized robot welding system

- Seam finding and AVC control

- Visual monitoring system

Hydrant Turbine Component

- 10-axis sychronized robot welding system

- 3-axis C-support with single-axis arc guide rail and 6-axis robot to achieve maximum working envelop and system flexibility

- MIG/MAG welding process

- Well-developed software for arc welding of medium/thick plate

Specification

| Single Shaft | Movable | Rotatable & adjustable | |

| C Frame Height | 3418mm | 3418mm | 3418mm |

| Arm Center Distance | 147z0mm | 147z0mm | |

| Rotary Degree | 180o | 180o | 315o |

| Rotary Speed | 18o/sec | 18o/sec | 24o/sec |

| Repeatability | 1.5 arc min | 0,2 arc mm | 1.5 arc min |