for ARC Weld Quality Management

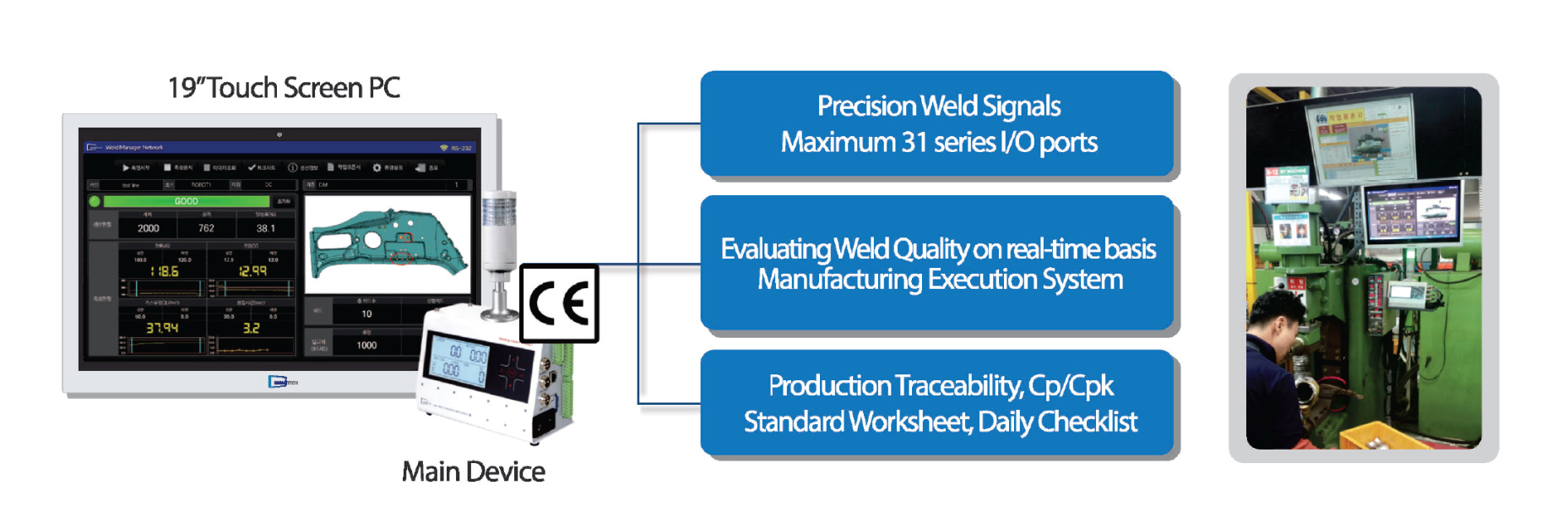

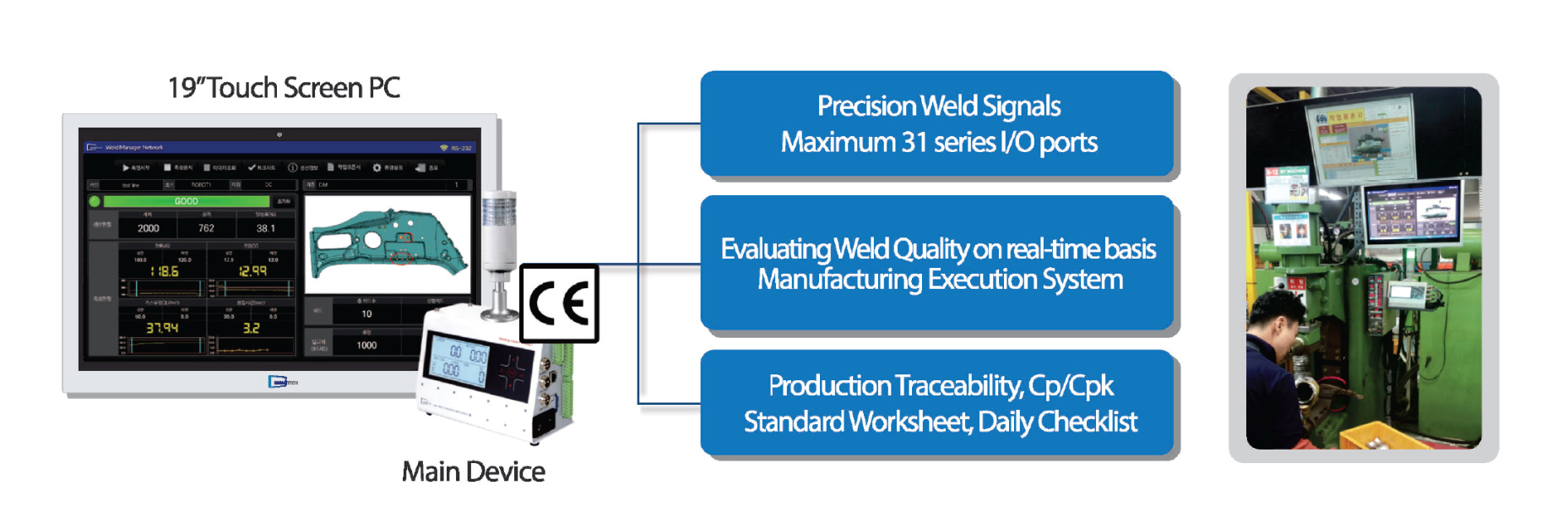

System Overview

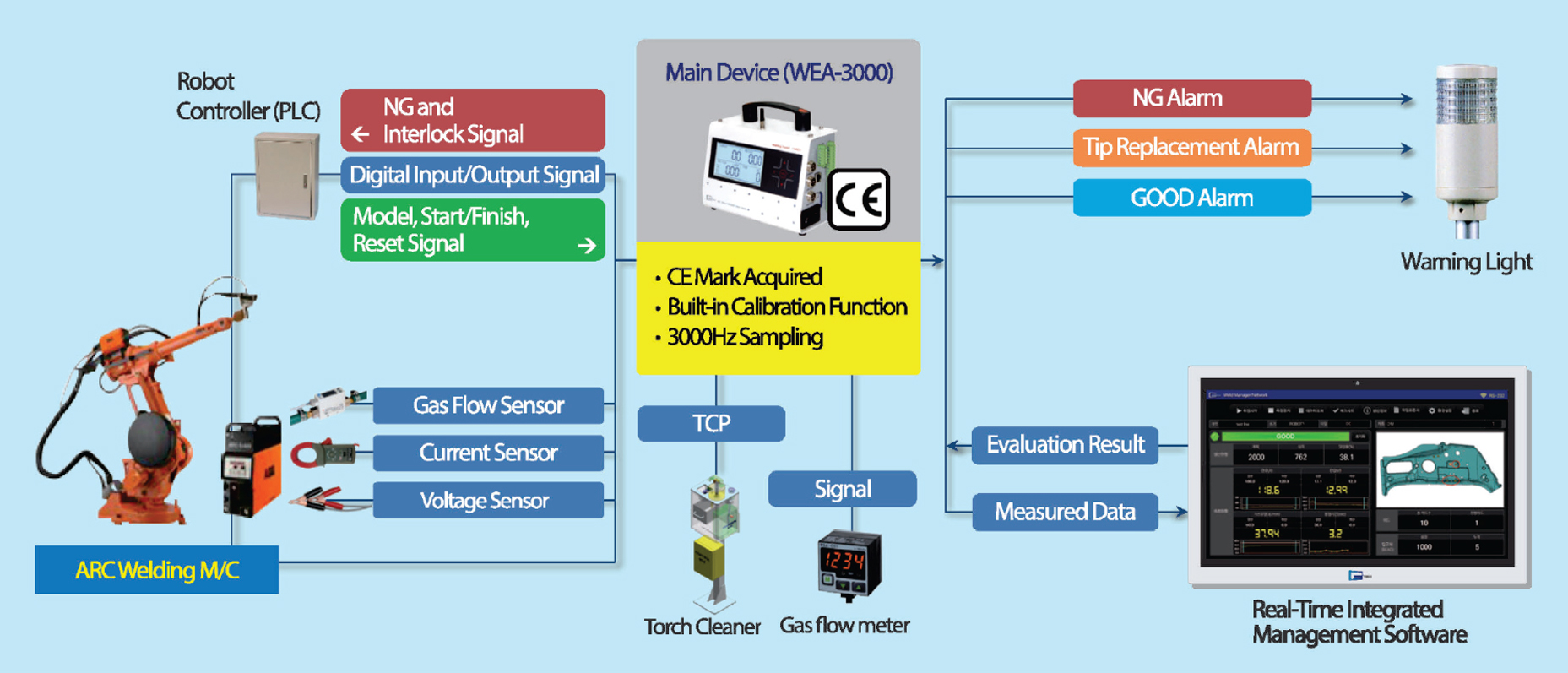

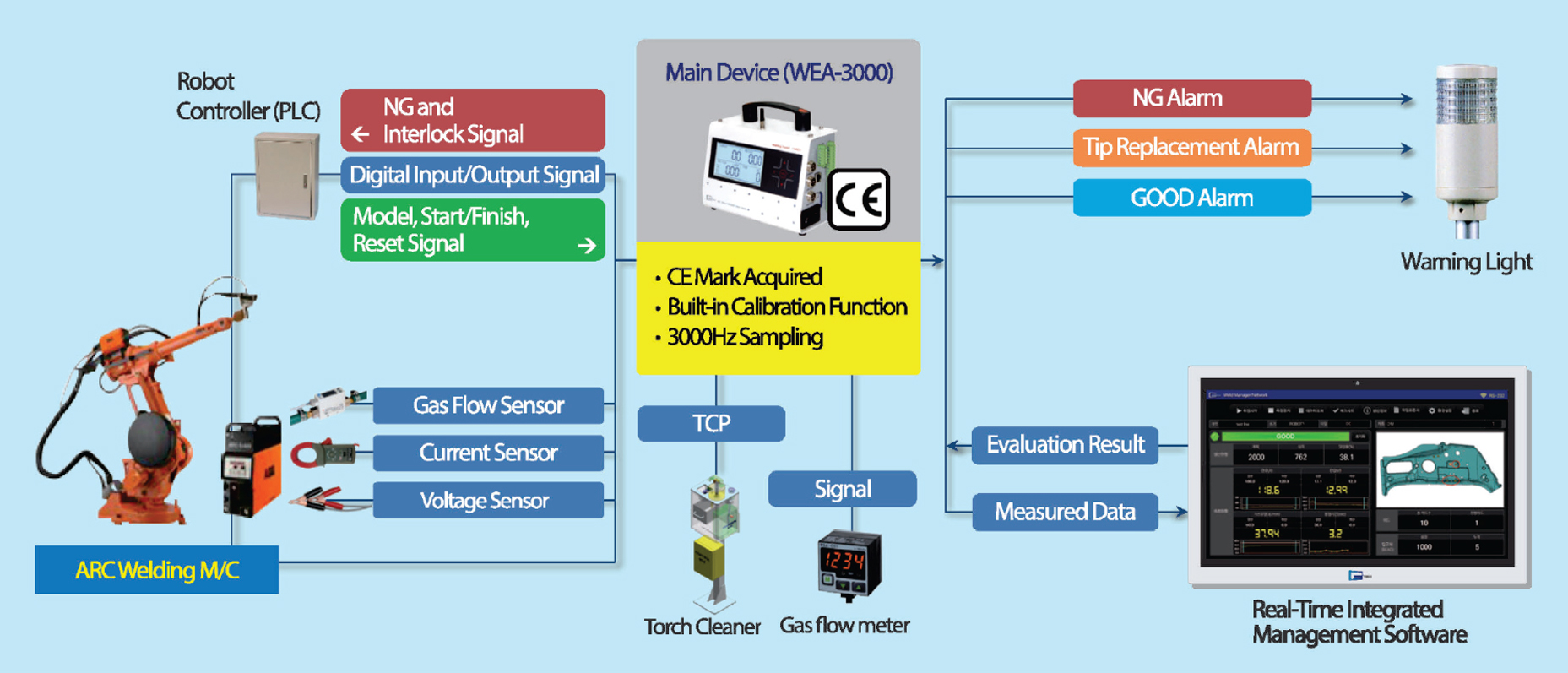

Standard Diagram of ARC Weld Monitoring System

Benefits

| OptimAal system for

SQ, 5-STAR, HIVIS |

Customized Monitoring System |

| Ideal for

real-time systematic |

Process loss reduced >Process stabilization >Reduced failure rates >Cost savings |

| Possible to manage

6 SIGMA control |

Report with one click |

WET-3000A Main Features and Specifications

| Control Items | Weld Current, Weld Voltage, Gas Flow, Gas Level(Optional) Weld Time, Tip Replacement and Dressing control Data Upper and Lower Limit Management TCP; Production count |

| Measuring Range | AC, DC, Inv.DC (Possible to measure up to Max 2000A) |

| Input/Output | Maximum 31 series signals (Controlled by system, model, bead) |

| Network S/W | Support up to max 25 units(optional) |

| Input Power | AC 200V/50~60Hz |

| Dimensions(mm) | Main-220(w) x 190(h) x 110(d) Touch Screen PC – 489(w) x 323(h) x 33(d) |